Mechanical Design: 9 Simple Ways to Improve Efficiency

Efficiency is the backbone of great mechanical design. Whether you’re a mechanical design engineer, a machine design engineer, or part of a mechanical design firm, optimizing workflows, reducing waste, and enhancing precision can save time and costs. The best mechanical design companies prioritize efficiency to stay ahead in a competitive market.

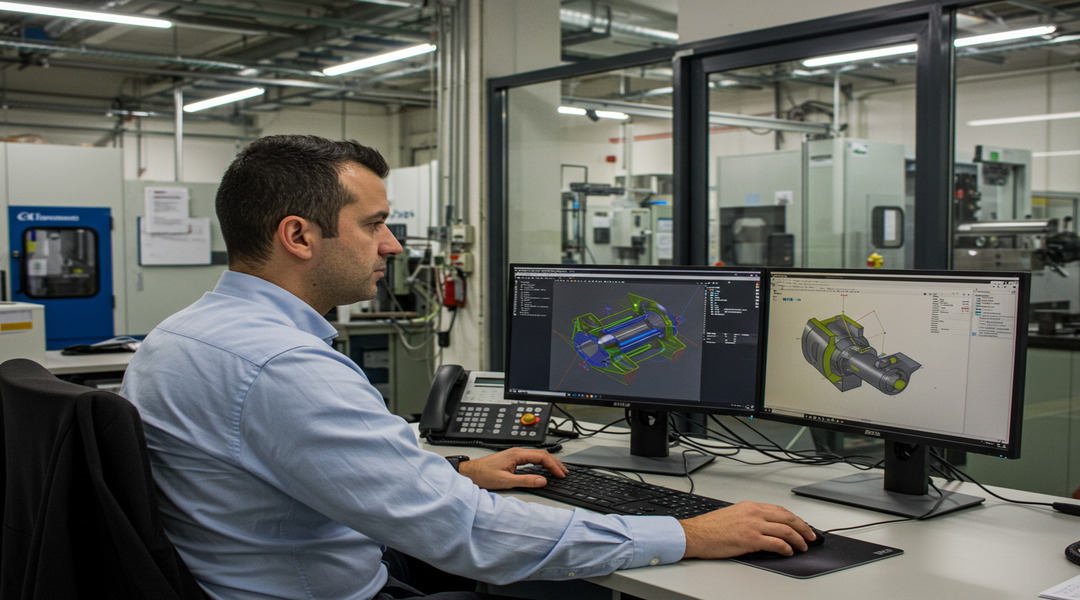

In today’s fast-paced industry, mechanical engineers rely on tools like mechanical CAD, 3D mechanical design, and AutoCAD for mechanical engineering to streamline processes. However, software alone isn’t enough. Best practices in product design mechanical engineering, opto mechanical design, and mechanical design technology make all the difference.

This guide explores nine proven strategies to improve mechanical design efficiency, from refining your design approach to integrating the latest tools and methodologies. If you’ve ever faced project delays, material waste, or design errors, these tips will help you optimize your workflow for success.

Table of Contents

1. Embrace Parametric and Modular Design

Using parametric modeling in mechanical CAD helps streamline modifications, reducing the need for repetitive manual adjustments. Modular design enables easy scalability, allowing mechanical design services to reuse components and reduce development time. A well-structured machine design approach ensures adaptability and efficiency.

Tip: Invest time in setting up standardized templates in AutoCAD for mechanical engineering or 3D mechanical design software to avoid recreating designs from scratch.

2. Optimize Material Selection

Material choice plays a critical role in mechanical design technology. Selecting the right materials can lower production costs, enhance durability, and improve performance.

Key Considerations:

- Lightweight materials reduce energy consumption in moving parts.

- Corrosion-resistant materials extend lifespan.

- High-strength alloys enhance structural integrity.

Utilizing simulation tools in mechanical CAD helps in selecting the most efficient material for each application.

3. Implement Design for Manufacturability (DFM) Principles

Efficiency isn’t just about designing a functional product—it’s about designing one that’s easy to manufacture. Mechanical design firms that adopt DFM principles minimize material waste, reduce production errors, and cut down costs.

Best Practices:

- Simplify complex geometries to reduce machining time.

- Design with standard parts to improve sourcing efficiency.

- Reduce the number of fasteners and joints for easier assembly.

4. Leverage Simulation and Prototyping Tools

Before finalizing a design, using 3D mechanical design simulations reduces costly physical prototyping. Software like AutoCAD for mechanical engineering and finite element analysis (FEA) tools help detect potential failures early.

Benefits:

- Virtual testing ensures design robustness.

- Reduces time-consuming physical prototyping.

- Enhances safety and reliability before production.

5. Enhance Collaboration with Cloud-Based Design Tools

A mechanical design firm thrives on seamless collaboration. Cloud-based tools allow mechanical design engineers and machine design engineers to work together in real time.

Advantages:

- Instant access to the latest design versions.

- Reduced errors due to outdated files.

- Faster feedback loops between design and manufacturing teams.

Popular platforms like AutoCAD for mechanical engineering and PTC Creo offer cloud-based features for enhanced efficiency.

6. Automate Repetitive Tasks with Scripting and Macros

Efficiency improves when repetitive tasks are automated. Many mechanical CAD and 3D mechanical design software tools allow scripting to speed up workflow.

Examples:

- Automate part numbering and BOM generation.

- Use macros to standardize hole placements.

- Batch-process design updates across multiple files.

Engineers using AutoCAD for mechanical engineering can create scripts to perform routine tasks, reducing manual workload and minimizing errors.

7. Standardize Documentation and Design Practices

Inconsistent documentation leads to inefficiencies in mechanical design services. Standardizing best practices ensures that designs are clear, accessible, and easy to interpret.

Best Practices:

- Maintain clear revision control.

- Use standardized symbols and annotations.

- Implement a centralized documentation system.

Following these steps improves communication between designers, manufacturers, and clients, reducing misinterpretations and production delays.

8. Integrate AI and Machine Learning in Design Processes

Advancements in mechanical design technology now allow AI-powered tools to optimize efficiency. AI-driven generative design helps explore innovative solutions beyond traditional methods.

AI Benefits:

- Faster optimization of structural elements.

- Predictive analysis reduces material waste.

- Automated design iterations save time.

Forward-thinking mechanical design companies leverage AI to stay competitive and improve design accuracy.

9. Prioritize Ergonomics and User-Centric Design

Beyond efficiency, designs must be practical and user-friendly. Product design mechanical engineering integrates ergonomics to improve functionality and reduce human errors.

Key Aspects:

- Optimize control placements for ease of use.

- Reduce unnecessary complexity in interfaces.

- Consider user comfort and safety in the final design.

Opto mechanical design and human-centered approaches ensure products meet real-world usability standards.

Conclusion

Improving efficiency in mechanical design is essential for reducing costs, streamlining production, and enhancing product reliability. By implementing these nine strategies, mechanical design engineers and machine design engineers can optimize their workflows and stay competitive in a fast-evolving industry.

Whether you’re working with mechanical CAD, exploring 3D mechanical design, or refining machine design an integrated approach, these best practices will elevate your design process.

Start applying these methods today and take your mechanical design technology to the next level!